#TBT A Quick Vampire Bite of Halloween

Hello! Continuing my Throwback Thursday posts, this time going with my love of hosting Halloween parties and the little ghoulish delights that need to be decorated. While it would have been okay to just put plastic vampire fangs on each cupcake, I wanted to make the fangs an edible candy treat!

Supplies:

Amazing Mold Putty

Plastic Children’s size Vampire Fangs

Wilton Candy Melts

Wilton Blood Red Sparkle Gel Icing

Red Velvet Cake Mix

Black Cupcake tin liners

White icing tinted blue-grey

Toothpicks

Sandwich baggies

Butter knife

I cleaned two child sized vampire fangs, with soap and water to prepare them for molding. I placed them on a black dinner plate so I had a smooth and contrasting surface to work on.

I mixed up some Amazing Mold Putty and molded it around the front portions of the vampire fangs. I was careful to press the Mold Putty up against the fangs to make sure I got a good molding of the fangs.

Once the Mold Putty was cured I removed the plastic fangs. To close up the grove created by the gum portion of the vampire fangs I mixed up and pressed tiny little wads of Mold Putty into the open portion of the mold as seen in the above photo. By doing this I would be able to place melted candy into the molds with no worry of the candy leaking out the back of the fang mold.

To keep the molds upright I placed a small teacup plate inside the large dinner plate and placed the molds snug inside the dinner plate and against the teacup plate. This will keep the molds in place while the candy is piped into the molds.

Following the manufacturer instructions I carefully melted the Wilton Candy Melts in a sandwich bag in the microwave. Once the candy was melted I snipped the end off a corner of the sandwich baggie and pipped the candy into the molds.*Make sure the candy is completely cooled before removing from the mold to make sure you don’t break off a fang. A quick trip in the refrigerator is a sure way to help your candy along!

I made up a batch of Red Velvet cupcakes, applied blue-grey tinted icing, dribbled some Wilton Blood Red Glitter Gel Icing and carefully placed a set of candy fangs on each cupcake.

I had so much fun making the candy fangs I made more than I needed for the cupcakes, so the extra fangs made fun addition to cranberry cocktails!

Until next time, safe travels!*This is an affiliate post, which means I received an assortment of products as a compensation for the creation of art. To read my full disclosure, click here.

#TBT The Upcycled Mummy’s Curse! A spoOky DIY

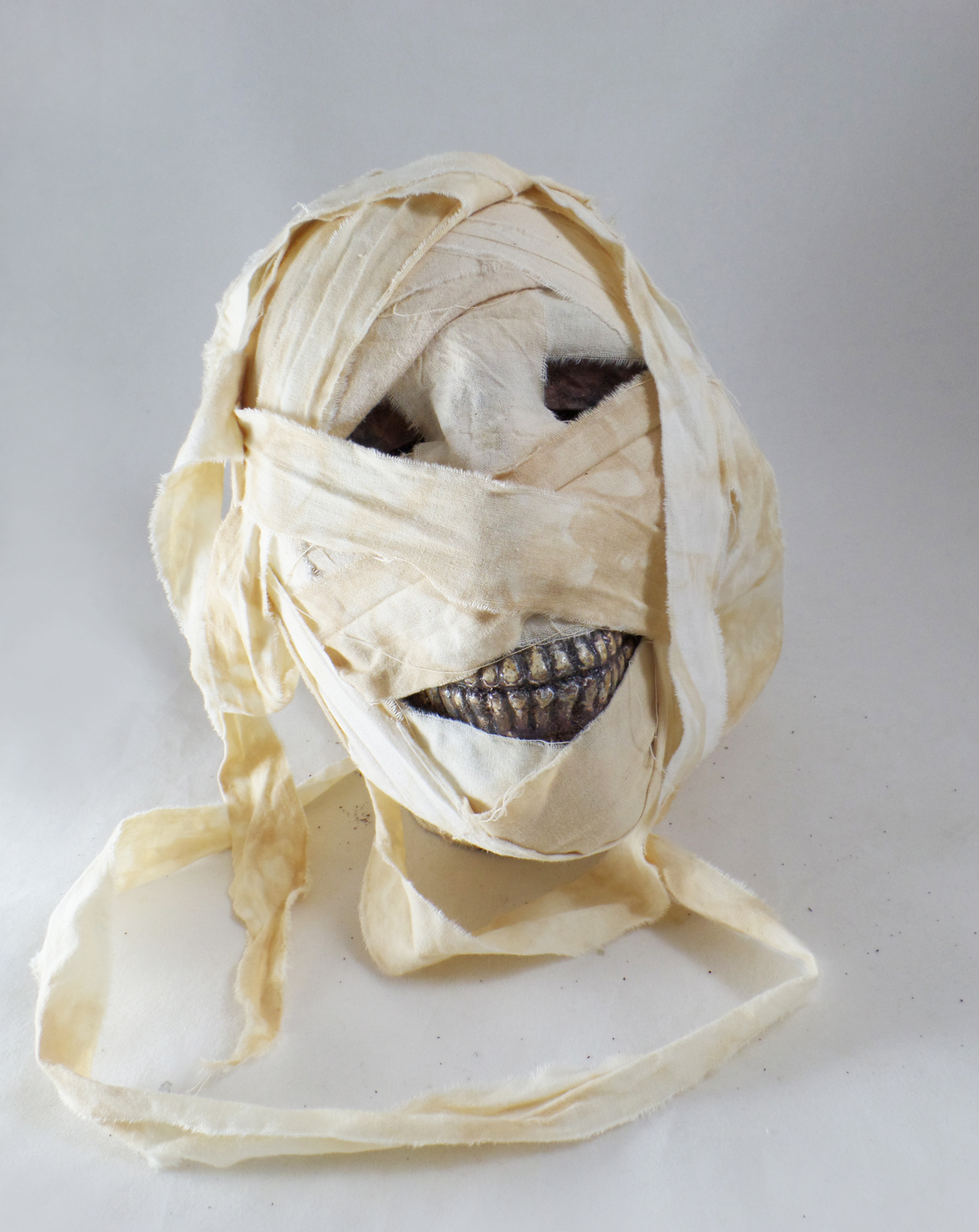

Continuing my Throwback Thursday posts, this time highlighting my love of Halloween, Ancient Egypt and upcycled crafts! Posted in 2015 on the Amazing Casting Products blog, I had some rather odd inspiration for this project and it all started with me finding some fun plastic Halloween skulls at a Thrift store. With two of them, I made Ghoulish Glam Skulls and the rest I saved for Halloween decor around the house.

While I was outside in the garden one of our dogs, Luna, decided to play in the house, the skulls were close to her toys and she cracked one of them. I of course couldn’t be angry with her playing though her rather adorable “I totally did NOT do that” face also helped. When I was about to throw out the skull, an idea came to me: why not use the cracked skull as a base for a Halloween mummy head prop?

Supplies:

Amazing Casting Resin

Alumilite Dyes

Liquitex Gloss and Matte Varnish

Acrylic Paint

Aluminium Foil and Paper Bags

Stir Sticks

Plastic Halloween Skull

Cotton Muslin Fabric

Black leaf tea bags

Beacon’s Gem-Tac

Paint Brush

Paper Tape Roll

Hot Glue Gun and glue sticks

With the crack being along the side of the eye socket and most of the left side of the skull I needed to stabilize the now-fragile skull. I thought of using Casting Resin but I needed to seal the hole before filling the skull with resin. I taped up the crack with clear packing tape, creating a temporary seal for the resin.

Knowing that if I were to fill up the whole skull with Casting Resin it would not only require a lot of resin but make the skull on the heavy side I needed to put some sort of filler inside the skull. Using used clean paper bags and crumpled aluminum foil I slipped them inside the skull through a hole in the bottom.

Next I made small batches of Amazing Casting Resin and poured it through the hole in the bottom of the skull. By pouring small batches and then tilting the skull I was able to make sure all of the inside of the skull was equally covered with resin, stabilizing the plastic skull. This process went very quickly because Amazing Casting Resin sets up in 10-15 minutes. I ended up using 3/4 of a resin kit to fill the inside of the skull.

Once I had filled up the inside of the skull I hot glued a tape roll to the bottom of the skull to create a neck for the mummy head. Any gaps between the tape roll and the skull I filled in with aluminum foil and hot glue.

I then mixed up some Casting Resin and poured it into the newly formed neck of the mummy head. I put some extra foil into the neck cavity and filled it up with more Casting Resin, using up all of the kit.

Once the resin was cured, I removed the tape from the now resin-filled crack and removed any excess resin spills off the skull.

Since not much of the plastic would be visible under the wrappings but I didn’t want it looking like a skull. I painted the skull with a mixture of yellow, brown and black acrylic paint. I glued on used tea bags to create eyelids and created a nose out of paper bags and tin foil. I glued on some loose tea grounds to give the look of sand/dirt and sealed it with Liquitex Matte Varnish.

To create wrappings: I dyed cotton muslin fabric in a bath of hot black leaf tea and bags. I let it soak for a few hours to stain and then let the fabric dry. Once dry I tore the fabric into 2 inch strips to make wrappings. I started applied the wrappings to the skull with a bit of Beacon’s Gem-Tac and started to wind it around the skull. I didn’t use any set pattern or style; I just had fun and made sure to cover up any of the more skull-like features of the head.

Once I was finished wrapping the skull I liked the overall look, but felt it needed something more to create the look of age.

Since real mummies still have old oils and resin still visible on the surface of their wrappings, I created some out of Liquitex Gloss Varnish mixed with some Brown Alumilite Dye. I used the varnish instead of resin because I wanted to control how it dripped and needed it to dry quickly. The Alumilite Dye allowed me to tint the varnish without losing the transparent nature of the varnish.

Once dry, this spooky décor is a perfect addition to my creepy curiosity cabinet on display for Halloween!

Until next time, safe travels!

This is an affiliate post, which means I received an assortment of products as a compensation for the creation of art. To read my full disclosure, click here.

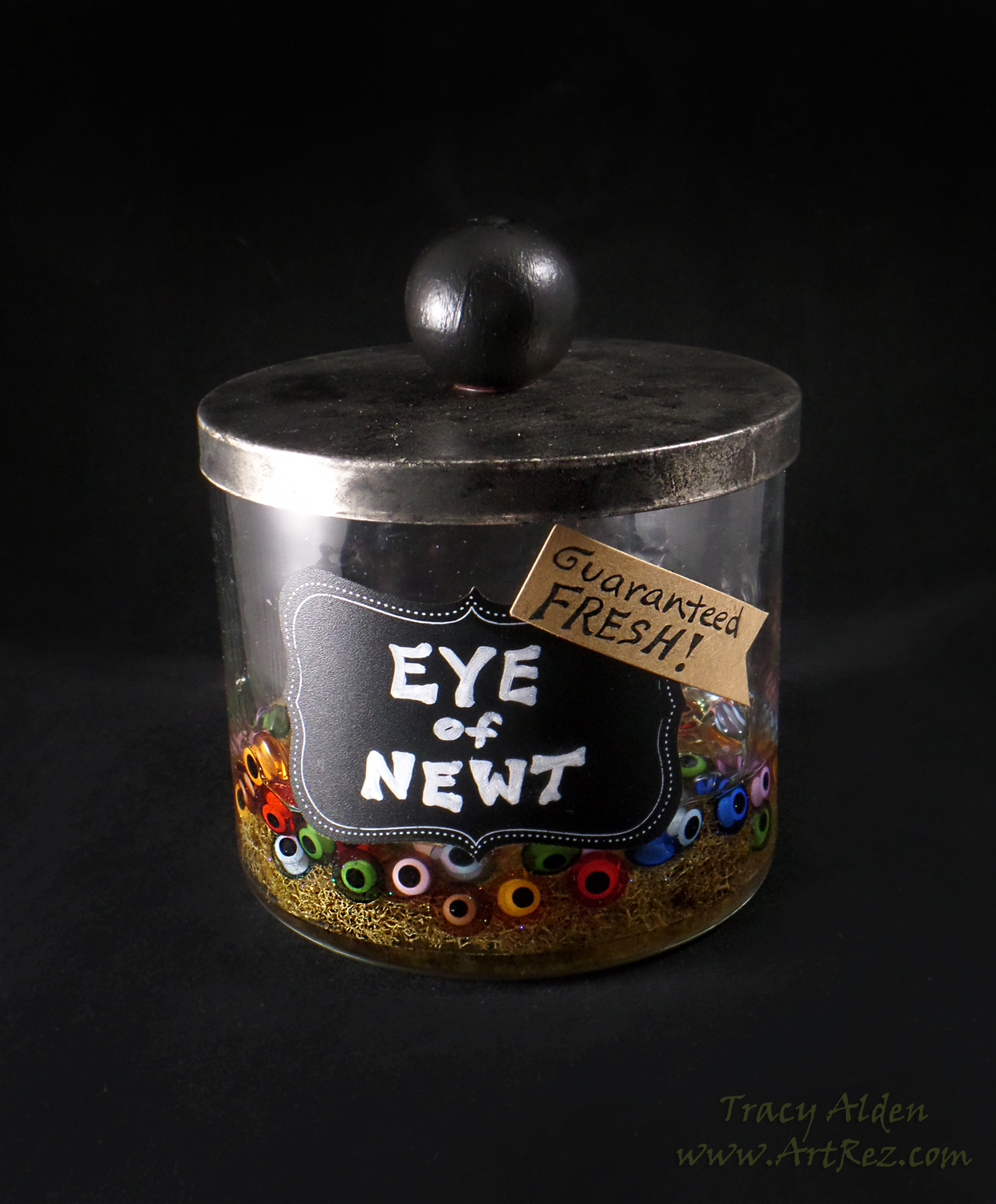

#TBT Sit for a Spell! DIY Eye of Newt Apothecary Jar

Kicking off my Throwback Thursday posts with one of my favorite upcycling Halloween crafts. Posted in 2015 on the Amazing Casting Products blog, this quick and easy project is perfect with Halloween coming up fast.

Taking inspiration from one of William Shakespeare’s most famous plays, Macbeth:

“Eye of newt, and toe of frog,

Wool of bat, and tongue of dog,

Adder’s fork, and blind-worm’s sting,

Lizard’s leg, and howlet’s wing,–

For a charm of powerful trouble,

Like a hell-broth boil and bubble.”That part of the play has a wonderful spooky quality, often inspiring all types of ghoulish displays and decor for Halloween. The interesting part is that most of those names of ingredients were not intended to be taken literal, but were herbalist or folk terms for common herbs and plants. In the case of “Eye of newt” it was referring to a type of mustard seed. However thanks to pop culture more often than not most people think of real newt eyes in a jar. So knowing some seeds in a jar isn’t that ghoulish of a Halloween decoration I decided to go with the pop culture version of making a jar with faux newt eyes.

Supplies:

A Glass Jar previously used for a candle

Resin

Moss

Eye Beads

Glitter (optional)

Chalk Sticker

Chalk Pen

Wood Bead

Black Chalk Paint

Sandpaper

I cleaned up a old jar that previously had a three wick candle with a metal lid, making it perfect for an apothecary jar. I picked this type of glass because it is tempered and can handle the heat often created by thick pours of curing resin.

I put some dried moss at the bottom of the jar to add some visual contrast. It would also help with adding some textured base to prop the fake eyes on so they wouldn’t all sink to the bottom.

I mixed up 3 fluid ounces of Amazing Clear Cast Resin and slowly poured it on top of the moss to cover it.

The moss became a bit dark after the resin started to soak into it, so before the resin layer started to cure I sprinkled a bit of micro crystal glitter* to give just a slight shimmer to the moss layer.

*The glitter is an optional step

For newt eyes I used transparent acrylic Eye of Warding beads carefully placed in the still wet resin. Recent popularity of the beads has had a lot of bead manufacturers making all kinds of the Eye of Warding beads out of glass, acrylic, clay and even recycled plastic.

*Take a trip to your favorite craft store to check out what types of beads they might have for you to use!

Once I let the first layer of resin cure for about an hour I added some more eye beads and little snippets of moss. I didn’t want to add too much. I wanted it to look like someone used the “newt eyes” a lot in their spells.

While the final layer of resin cured I worked on the lid to the jar. To bring down some of the bright silver tone of the lid I used some sandpaper and little bit of chalk paint to give it an aged look. A painted wooded bead, glued on top of the lid, gave it a pull knob.

With a chalk board sticker for a label the jar was finished and not a single newt harmed! 🙂

Until next time, safe travels!

*This is an affiliate post, which means I received an assortment of products as a compensation for the creation of art. To read my full disclosure, click here.

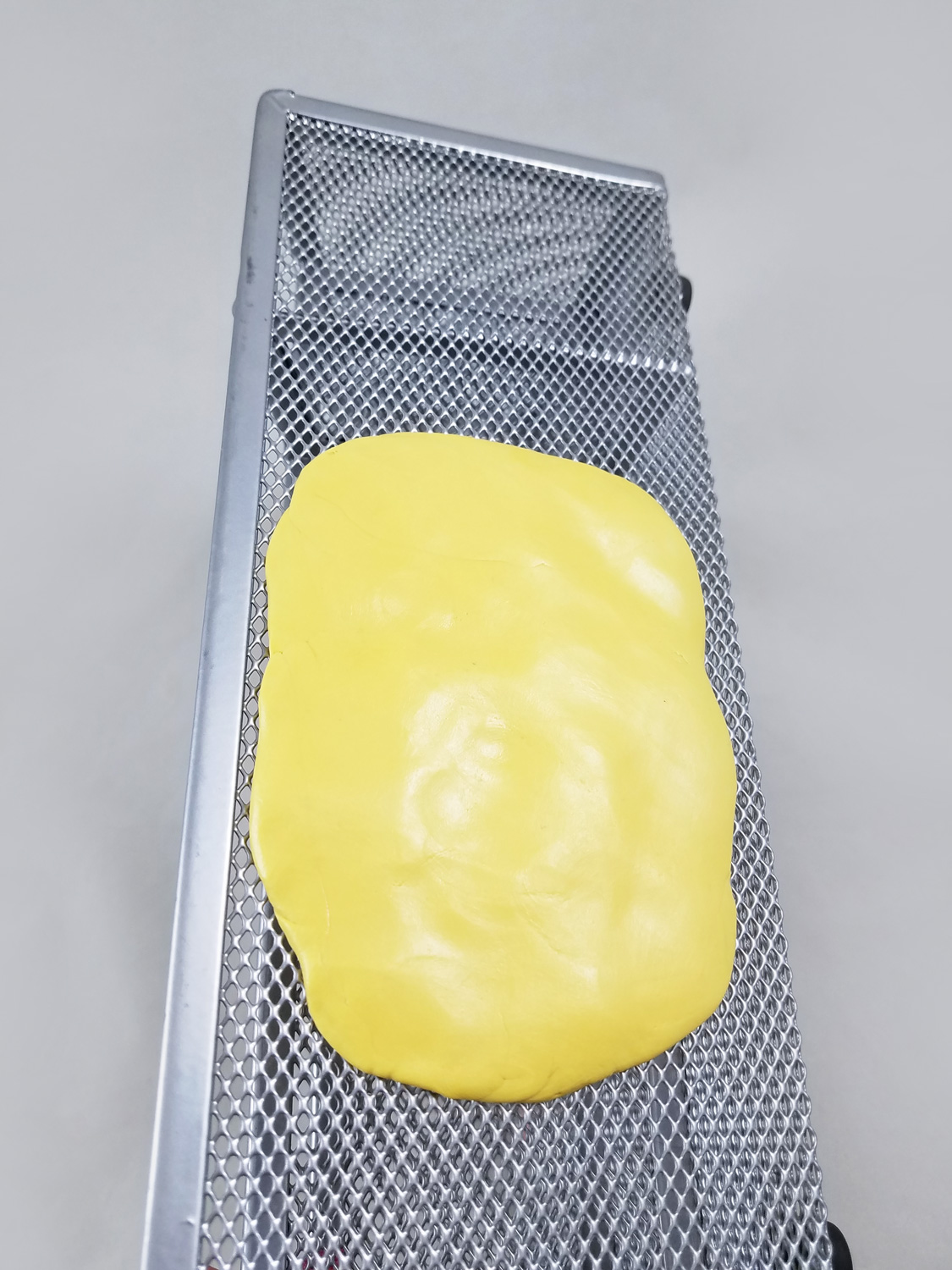

The Mermaid’s Necklace, a #Cre8time fish-tale

A great inspiration for my art is looking for and finding textures to duplicate and/or mold. While my project might look like something from the sea it started in a by far more mundane environment, my office. My metal pen, paper and paperclip holder is made out of mesh, a delicate diamond pattern, reminiscent of tiny fish scales. With the help of Amazing Mold Putty I could transfer this lovely pattern to Premo Accents polymer clay to create a necklace fit for a mermaid!

Supplies:

Amazing Mold Putty

Alumidust

Alumilite Metallic Powder

Premo Sculpey Accents Multipack 12 pc Mixed Effects(using Bright Green Pearl, Sunset Pearl, Peacock Pearl from this pack)

Premo Sculpey Accents Translucent

Sculpey Glaze Gloss

Acrylic Roller

Stylus (small sizes)

Pasta Machine (optional but helpful)

Ceramic Tiles

Craft Knife

Small Paint or Makeup Brush

Beacon Gem-Tac Glue

Rhinestones

Silver tone jewelry chain and jumprings

Metal mesh office pen and note holder or a piece of heavy weight mesh

I mixed up some Amazing Mold Putty {CLICK HERE to view mixing/preparation}, and applied it to the largest open part of the mesh office supply holder. I was careful to press the Mold Putty through the mesh to get detail, but not too far that the mold putty would seep through creating weak points and holes in the mold.

Once the Mold Putty was cure I carefully peeled it off the wire mesh. Now I had a perfect texture plate that had a close resemblance to tiny fish scales.

Using a pasta machine (devoted to craft use only) set on the thickest setting, I conditioned some Premo Accents Translucent polymer clay. I added the translucent clay to one half of the Bright Green Pearl, Sunset Pearl, Peacock Pearl clay bricks found in the Premo Accents Multipack.

*The addition of the translucent clay to the colored clay creates a look of slightly translucent fish scales once the clay is baked.

Next I cut my conditioned clay into wedges and pushed the edges together as seen in the above photo. What I created is the start of what is call an Offset Skinner Blend technique. This technique was developed by a talented polymer clay artist named Judith Skinner in the 1990s, which creates a stunning and smooth blend of colors in polymer clay when clay is cut into triangles and then run through a pasta machine multiple times. In the photo you can see those are not triangles, those are purposefully offset and trimmed so that it will create areas of pure unblended color with the blended portions, giving a more vibrant contrast in the final blend.

Using the thickest setting of the pasta machine I inserted the clay sheet, with the edge of of all three colors first; this made sure all the seams are pressed lightly together. I caught the clay sheet as it came out of the pasta machine.

I then folded in half, top to bottom, the clay sheet making sure to match the colors on the sheet edges and once again run it through the pasta machine. I did that 10 more times, folding and rolling the clay sheet in the same direction.

*If you are new to trying this technique try it first with scrap clay to practice. Polyform Products has great video on how to create a Skinner Blend HERE.

This gradient of colors is 10 fold-and-roll passes through the pasta machine, I wanted an even smoother transition of colors and ran the clay sheet a few more times through the pasta machine.

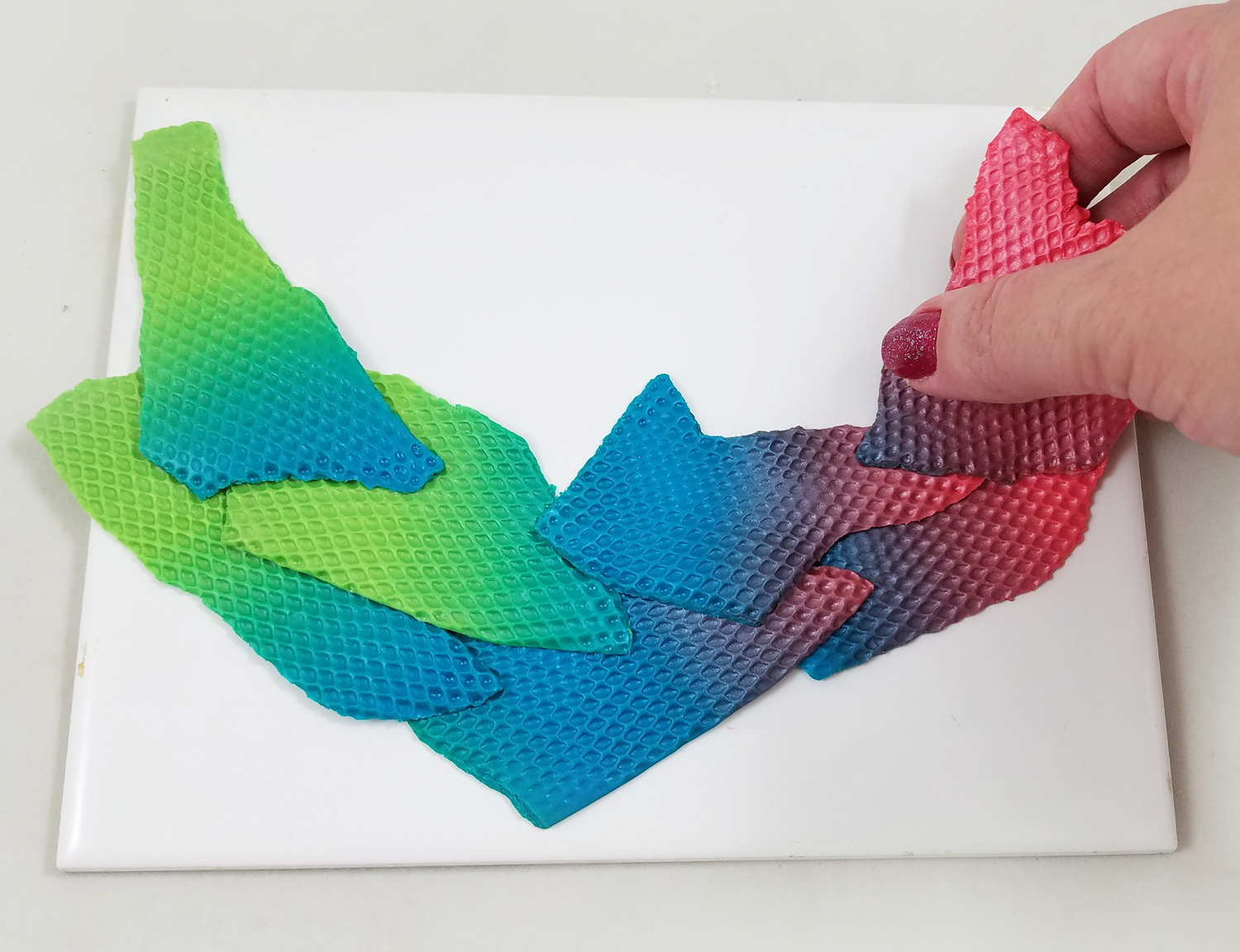

Once I got my clay sheet to the desired blend I carefully tore the gradient piece of clay into smaller pieces. This might seem a bit odd to do after all of the hard work getting a smooth gradient but stay with me!

Taking each small torn piece of clay I placed it on my Amazing Mold Putty mesh texture plate and rolled an acrylic roller in a firm but consistent motion, careful to get as much texture as possible impressed into the soft clay.

Each textured piece of clay was placed on top of each other in a semi-circle shape, and pressed lightly at the edges to help stick each piece together.

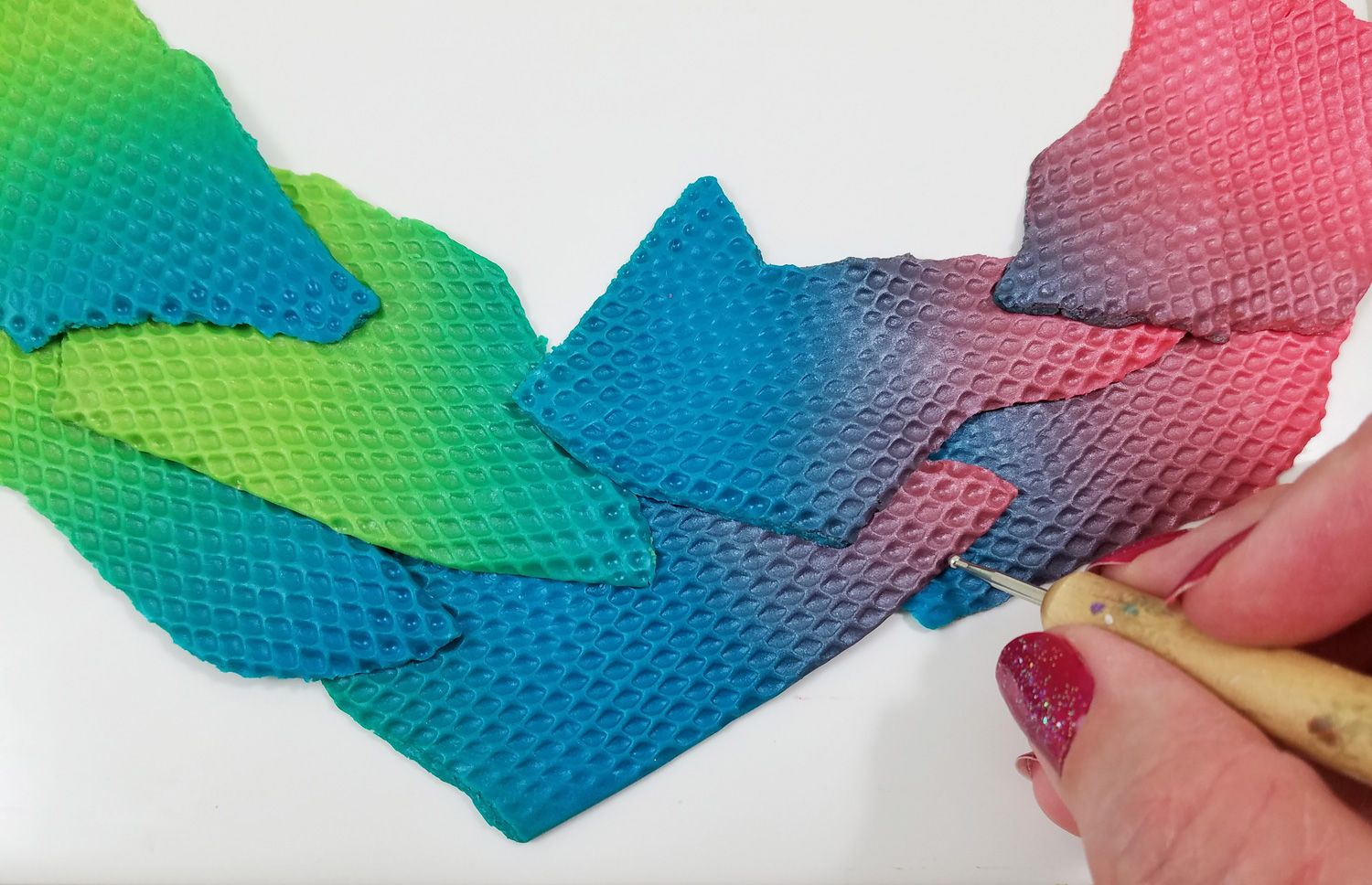

Using a small stylus I fixed any portions of the clay that didn’t get a complete impression of the texture plate and pressed the edges more firmly together in the scale-like indents.

I twisted up half a paper towel into a tube shape, curved it into a semi-circle and placed in on the my ceramic tile. I then carefully removed my curved clay piece off the tile and laid it on top of the twisted paper towel, pushing the clay sides down every so slightly creating a raised portion. The raised form would give the clay more dimension and allow for a more dynamic application of metallic powders.

I dipped my finger in some Silver Alumilite Metallic Powder and gently ran my finger across the raised textured surface of the clay, highlighting the scaled texture. Using a soft makeup brush I applied Interference Red and Green Alumidust into the lower portions of the scale texture on the clay. I applied only a very small amount of the Black Alumidust to the edges of the clay. The powders bonded to the uncured polymer clay without the addition of a glue or sealant.

I made two holes on the top left and right of the necklace with a stylus; these would become holes to place jumprings and chain through once the clay is cured.

I then put the tile with the clay necklace into a toaster oven, heated per manufacturer instructions, to cure.

I painted on a coat of gloss Sculpey Glaze over the now cured piece of clay and let it dry per manufacturer instructions.

I applied little dots of Beacon’s Gem-Tac glue on the edges of the scales and I added flatback crystal rhinestones. I put jumprings through the two holes on each side and attached jewelry chain. Now the necklace was ready to wear!

Happy Holidays and until next time, safe travels!

This is an affiliate post, which means I received an assortment of products as a compensation for the creation of art. To read my full disclosure, click here.

2018 Creativation Trade Show with Amazing Casting Products

The Creativation Trade show, held in Phoenix, Arizona is the must-go event for craft and hobby industry professionals. It is held by Association For Creative Industries or AFCI, showcasing the many facets of the creative industries from edible arts, painting & drawing, kids crafts, sewing & fabric, paper crafts and more. This year’s 2018 show was a plethora of arts and crafts manufacturers, new products, demos, classes, and networking opportunities.

Once again I was a demonstrator at the Amazing Casting Products/Alumilite Corp booth at Creativation! Here we are first day, right before show floor opening happy to have the booth up and running before the rush of attendees. It was a pleasure and honor to being working with such talented and devoted people!

So many samples were showcased in every corner of the booth!

The Amazing Casting Products Design Team had sent in a wonderful array of projects.

Anything from home decor, kitchen wear, mixed media, jewelry, toys, garden decor, and fine art applications could be found in the booth.

The demo area always had some sort art going on.

With so many samples there was bound to be some art application that would catch the interest of an attendee.

All three days I did demos; First day “Frozen in Time” How to embellish mixed media projects combining Amazing Clear Cast Resin with powders, dyes, stamps, found objects and more! Second day “Crafting Conversation Curios” How to mold and create unique handmade resin pendants, charms and curios with Amazing Casting Products! Third day “Wearable Art, Clay Time” Exploring the creative possibilities of wearable art that can be achieved using Amazing Casting Products and polymer clay! Manufacturer partner, Polyform Products

Yours truly working on the “Crafting Conversation Curios” demo.

Amazing Casting Products Design Team Leader Susan M. Brown starting with her “Moldmaking 101” demo. At this demo people learned how to make quick and easy push molds using Amazing Mold Putty that could be used with Amazing Casting Resin, polymer clay, chocolate, fondant, plaster, soap, and more! Susan also did a fun interactive game “Texture THIS?!” exploring texture plates with polymer clay while learning quick and easy techniques to make and use texture in varied mediums/applications. Game entrants were entered to win a prize package of Alumilite Corp/Amazing Casting Products & Polyform Products.

The wonderful and talented mixed-media artist Cat Kerr‘s demo “Bezel Bonanza” on the first day of the show. Demonstrating three resin bezel techniques that add dazzling dimension and texture to empty bezels combining Amazing Casting Resin, Amazing Clear Cast Resin, and polymer clay. Manufacturer partners, Polyform Products and Nunn Design. A video tutorial of her demo have be found here: Clay and Resin Dimensional Pendant

Cat’s second day of demos was “Personalized Photo Holders” was about making quick and fun personalized gifts using Amazing Mold Putty and Amazing Casting Resin.

Creativation came and went so quickly it almost seems a dream filled with good times, amazing creative people, inspiration and a gateway into the creative industries. Hope to see you there next year!

Until Next Time, Safe Travels!