Faux Ancient Egyptian Pendants

One of my favorite pastimes is to go visit museums and flip through books with ancient jewelry collections. The ingenuity, craftsmanship and raw talent in ancient work is a true inspiration.

One of those ancient testaments to ingenuity is Ancient Egyptian Faience, known as the world’s oldest known form of glazed ceramic and a precursor to the earliest forms of glass making. While it shares the name faience with the tin-glazed pottery associated with Faenza in northern Italy, it is not true faience. Ancient Egyptian Faience is not made of clay at all but type of frit, a mixture of sand, quartz, silica, calcite lime and a mixture of alkalis. To the ancient Egyptians, it was known was known as “tjehnet” which means brilliant or dazzling. Often crafted into beads, pendants, figures, tiles and other small objects, using push molds or sculpted by hand, then heated to create lovely glazed pieces of art. It was used as a imitation of semi precious stones, such as lapis lazuli and turquoise, though many colors could be achieved by changing some of the ingredients of the frit mixture.

I wondered, how I could make something that looked like Ancient Egyptian Faience but without the need of a kiln? Using real Egyptian Faience as my model, such as those in the above photo, gave me a good idea of what colors and textures I wanted to match. While it is very easy to create the shapes out of any number of air dry and oven bake clays, the glazed appearance of much of the Ancient Egyptian Faience was going to be tricky. I got to thinking how Amazing Casting Products’s Amazing Clear Cast Resin on top of polymer clay could appear like a glaze and more akin to the lovely ancient work.

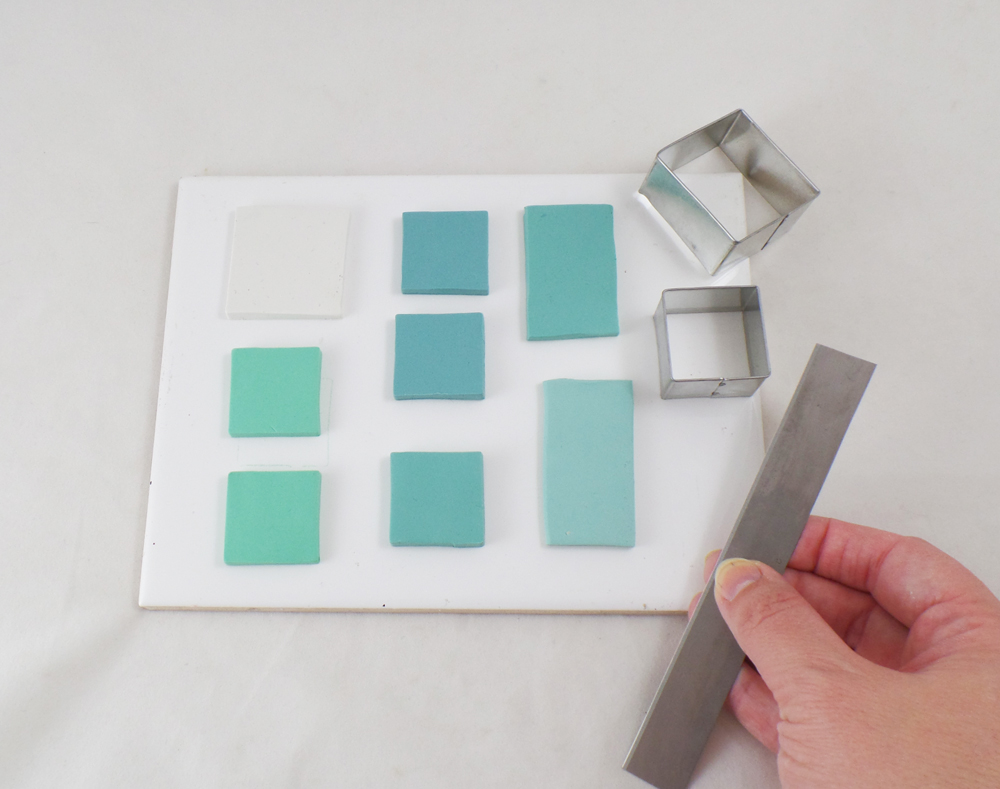

I started with conditioned polymer clay, in the color tones of blues and greens, betting that a base color of those hues would give me the best results. I also conditioned a piece of white polymer clay as a color test. I then cut all pieces into sizes and shapes good for pendents.

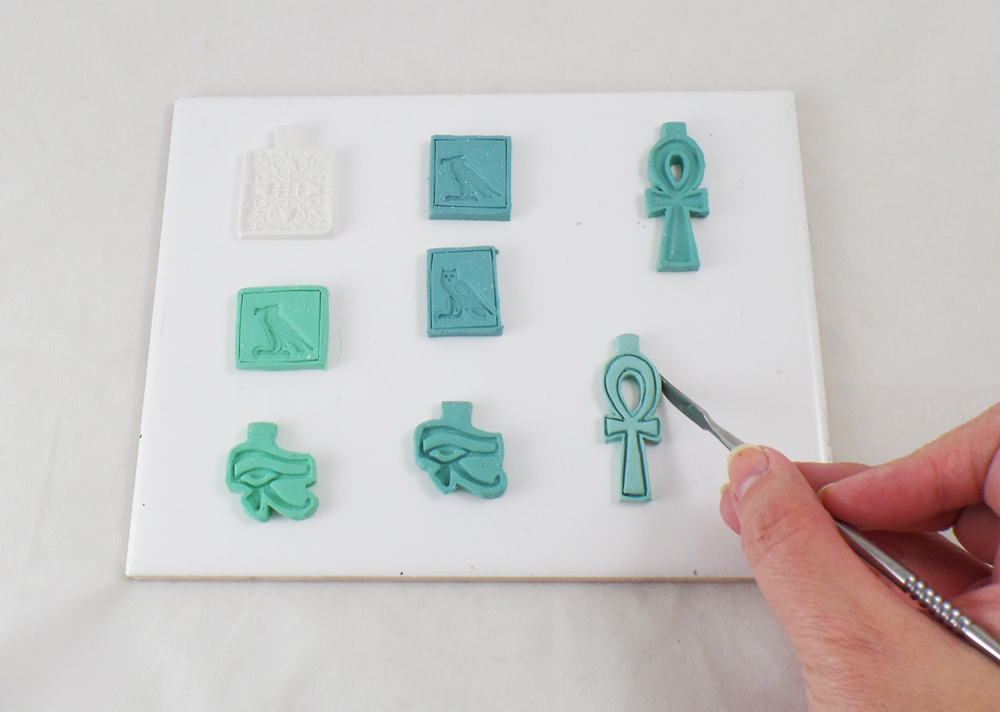

I went through my collection of stamps and charms, picking ones that were Egyptian themed. I sprayed the object to be pressed in the clay with water to act as a stamp release from the clay and pressed firmly into the clay.

I trimmed the pieces of clay close to the stamped images, smoothing edges and defining details of the stamped images.

After curing the polymer clay by manufacturer’s instructions, and once the pieces were cool, I trimmed off any rough edges on the clay pieces with a craft knife.

I applied a thin layer of Liquitex Gloss Varnish to all of the pieces and before they dried rubbed on a light layer of Alumidust.

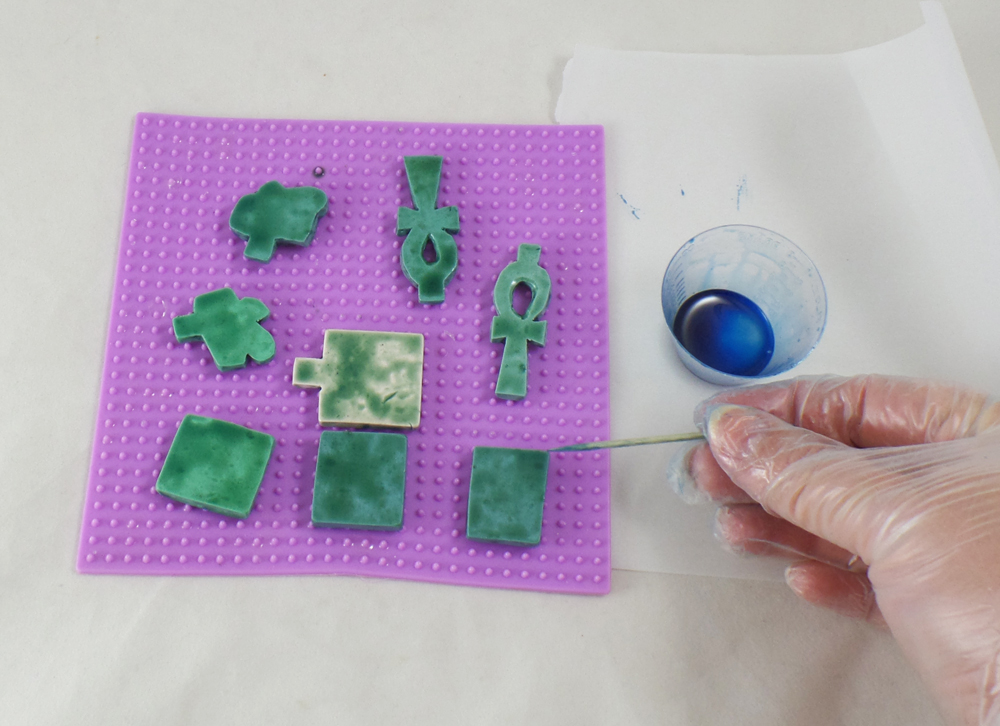

I mixed a very small amount of blue and green Alumilite Dyes with Amazing Clear Cast Resin, making sure to fully stir the dyes into the resin and let it sit for 10 minutes.

By letting the resin sit for 10 minutes, the resin will be thicker and stick more to the polymer clay pieces. I carefully applied the resin to the back and sides of the pendants with a toothpick first and let them cure completely, as per manufacture instructions, before moving onto the next step.

After the back of the polymer clay pieces were dry I applied resin to the front of the pieces with a toothpick, making sure to get all the groves and indents of the stamped images. I let this layer of resin cure completely.

Once all of the pieces were fully cured I carefully drilled holes to put beading wire and thread through each piece.